Specific Product Information & Principal Uses For Each Thickness & Type

NOMEX® Brand paper

Commercial types:

Type 410- The Original and most-used type of calendered paper

Type 410- The Original and most-used type of calendered paper

Available in 11 thicknesses from 2 through 30 mils (0.05 through 0.76 mm)- serves almost all electrical end uses for NOMEX® aramid paper - good properties in all catagories. Comprises over 80% of total paper sales volume for NOMEX® aramid paper in electrical insulation markets. Has very low porosity due to the highly calendered surfaces, but 2 mil (0.05mm) and 3 mil (0.08 mm) grades can be impregnated with oils and resins in a relatively short time. All grades 7 mils (.18 mm) and thicker meet UL Standard 94V-O.

2 mil (0.05 mm)- used for magnet wire wrap for large transformers or for laminating for motor slot liners. Usually used in multiple layers such as overlapped on wire. Occasionally used for layer insulation in very small transformers where small wire needs very flexible insulation and voltages are low between layers. Also used as a substrate for pressure-sensitive tape, for creping, laminating, etc.

3, 5, 7 mil (.08, .13, .18 mm)- used for many applications, but major uses are layer insulation in transformers, laminating especially 3 mil (.08 mm), and 7 mil (.18 mm) paper is also used as slot liner in small motors. It is also used for magnet wire insulation in some high-performance designs.

10 mil (.25 mm)- used in many designs of transformers, and the largest volume sales product in the NOMEX® aramid paper line of products. Also used as slot liners in a range of AC and DC motors. Other uses include unvarnished barriers in electronic equipment, made possibly by its excellent flame resistance and good cut-through resistance.

12 and 15 mil (.30 and .38 mm)- Motor slot liners and phase insulation, core, layer, and barrier insulation in large transformers, high voltage barriers in switchgear, etc.

20 mil (.51 mm)- Slot liners and phase insulation in large rotating equipment, preformed wedges for small motors, core, layer, and barrier, tap and lead insulation for large transformers. End laminations for motors.

24 and 29 mil (.61 and .74 mm)- Usually used for preformed wedges in medium-sized electric motors. Sometimes used for phase insulation in large motors. Relatively expensive to buy due to high density and high stiffness resulting from heavy calendering. Somewhat brittle for the same reason- will crack if bent sharply when dry, so it is generally hot-formed.

30 mil (.76 mm)- Widely used in large high-voltage transformers

as core, barrier, tap and lead insulation and sometimes as end filler.

The same weight as 29 mil but more flexible and resilient. Preferred for

uses other than wedges.

Standard Width : 914 mm (36")

| Thickness | Initial Tear Strength | Tensile Strength | Approximate Length | Net Weight | Dielectric

Breakdown Volts |

|||

| lbs | lbs/in | 11-1/2" OD | ||||||

| Inches | Machine | Cross | Machine | Cross | Meter | Lineal Yds. | Kgs(Approx.) | |

| 0.002 | 1.3 | 2.5 | 25 | 10 | 1150 | 1250 | 42 | 950 |

| 0.003 | 1.9 | 3.5 | 40 | 20 | 770 | 840 | 45 | 1730 |

| 0.005 | 3.6 | 7.3 | 80 | 40 | 440 | 480 | 46 | 3350 |

| 0.007 | 5.6 | 11.0 | 130 | 65 | 320 | 350 | 51 | 6150 |

| 0.010 | 9.2 | 16.0 | 175 | 85 | 240 | 260 | 54 | 8250 |

| 0.012 | 11.4 | 21.0 | 220 | 115 | 183 | 200 | 52 | 10330 |

| 0.015 | 16.0 | 26.0 | 275 | 150 | 155 | 170 | 56 | 12400 |

| 0.020 | 2401 | 36.4 | 375 | 215 | 120 | 130 | 60 | 16100 |

| 0.024 | 32.9 | 42.0 | 470 | 305 | 101 | 110 | 64 | 19800 |

| 0.029 | 38.5 | 46.8 | 535 | 380 | 82 | 90 | . | 21700 |

| 0.030 | 43.0 | 54.1 | 520 | 350 | 82 | 90 | 61 | 21300 |

Type 411- Uncalendered aramid paper

Has a few specialized uses, but weak physical properties restrict its sales. Prices under half of that of Type 410. Available in 5 thicknesses from 5 mil to 23 mils (0.13 to 0.58 mm). Uncalendered, soft, low strength. Highly saturable to resins, varnishes, and oils, and this greatly improves the electrical strength. Thermally equivalent to Type 410.

5 mil (0.13 mm) and 7 mil (0.18 mm)- used as layer insulation in fairly large transformers. The principal uses are as precursors for 2 and 3 mil Type 410, respectively. Fair absorbency, but low physical strength, low dielectric strength, and low cut-through resistance limit uses. Thermally excellent, offering excellent value in uses not requiring high physical properties.

10 mil (0.25 mm) and 15 mil (0.38)- Used for layer insulation in medium-sized transformers, punched parts, and shunt insulation in small ferroresonant transformers. As in the case of 5 and 7 mil, lower properties limit uses, but lower price often results in excellent value.

23 mil (0.58 mm)- Thickest grade of Type 411, mostly used in

transformers as layer insulation or end filler. The basis weight is high

enough that physical properties are fairly good despite lack of calendering.

Standard Width : 965mm (38")

| Thickness Inches | Initial Tear Strength | Tensile Strength | Approximate Length | Weight

Kgs (approx.) |

Dielectric Breakdown | |||

|---|---|---|---|---|---|---|---|---|

| lbs. | lbs./in. | 11-1/2"OD | ||||||

| Machine | Cross | Machine | Cross | Meter | Lineal Yds. | Volts | ||

| 0.005 | 0.6 | 1.2 | 10 | 5 | 530 | 580 | 20 | 1250 |

| 0.007 | 0.9 | 1.7 | 15 | 8 | 350 | 380 | 21 | 1900 |

| 0.010 | 1.2 | 2.2 | 18 | 10 | 260 | 290 | 20 | 2550 |

| 0.015 | 2.1 | 3.4 | 27 | 16 | 165 | 180 | 21 | 4250 |

| 0.023 | 3.5 | 4.7 | 32 | 22 | 90 | 100 | 18 | 6000 |

Type 414- Most "conformable" grade of calendered aramid paper

Like Type 410 but "tougher", less stiff. Intended originally for motor slot liner, but also good for transformers due to easy wrapping, better varnish adhesion than Type 410. Available in 5 thicknesses from 3.4 to 15 mils (0.09 to 0.38 mm). More absorbent than Type 410.

3.4 mil (0.09 mm)- Used almost exclusively as linear wrap on conductor in field coils for starter motors in automobile engines. This was a specially-developed product for this use, thougher than 3 mil Type 410, and no other important uses have developed. However, it has been adopted for wire wrap in distribution transformers in Europe, and this use in growing. It is also used in certain NMN laminate constructions.

7 mil (0.18 mm), 10 mil (0.25 mm), 12 mil (0.30 mm), and 15 mil (0.38

mm)- These grades were developed to meet the need for "tougher" slot

liners, and are still largely used for that purpose. However, they also

have better surface adhesion to resins, and therefore have found some use

in transformers, particularly where less stiffness is desirable.

Standard Width : 914 mm (36")

| Thickness Inches | Initial Tear Strength | Tensile Strength | Approx. Length | Weight

Kgs. (Approx.) |

Dielectric Breakdown | |||

|---|---|---|---|---|---|---|---|---|

| lbs. | lbs./in. | 11-1/2"OD | ||||||

| Machine | Cross | Machine | Cross | Meter | Lineal Yds. | Volts | ||

| 0.0034 | 2.2 | 4.4 | 30 | 15 | 658 | 720 | 51 | 1950 |

| 0.007 | 5.0 | 10.8 | 100 | 50 | 320 | 350 | 51 | 5300 |

| 0.010 | 7.7 | 16.0 | 140 | 70 | 238 | 260 | 54 | 7850 |

| 0.012 | 9.4 | 21.0 | 175 | 85 | 183 | 200 | 51 | 9600 |

| 0.015 | 12.5 | 25.0 | 215 | 115 | 155 | 170 | 55 | 11750 |

Type 416 & 464- Special aramid products for laminates

Special grades sold only for laminating (not sold through distributors except in laminated form) for motor slot liners and similar uses. Available in 3 thicknesses from 2 to 5 mils (0.05 to 0.13 mm). Lower thermal rating, special preparation and marking for laminating.

2 mil (0.05 mm), 3 mil (0.08 mm), 5 mil (0.13 mm)- All these grades are sold only to laminators, and the products are intended to be used in NMN laminates for motor slot liner and phase insulation, competing with DMD laminates or CMC (glass/polyester film) laminates. The temperature tolerance is inferior to T-410 but physical properties are generally similar. Because it is always used in laminates, defects are not patched, even pinholes, and property limits are lower. Price can therefore be less than Type 410 and other top-quality papers.

Type 418- Calendered aramid paper with mica for highest performance

Best electrical and flammability properties, with premium price due to mica content. Intended for high-voltage equipment where corona is a serious problem, but also offers outstanding flame resistance due to 50% mica content. Available in 5 thicknesses from 3 to 14 mils (0.08 to 0.36 mm). Fairly absorbent to resins, varnishes, and oils.

3 mil (0.08 mm)- Used for high-voltage wire wrap in certain special high-voltage dry-type, usually gas-filled, transformers.

5 mil (0.13 mm) and 8 mil (0.21 mm)- Used for wire and coil insulation in high-voltage form-wound motors. Also, they are used in some high-voltage transformers, such as microwave oven power suppliers.

10 mil (0.25 mm)- Mostly used for layer and outer insulation for small high-voltage transformer, such microwave ovens and high-intensity discharge (HID) lighting transformers.

14 mil (0.35 mm)- Used for coil wrapper in microwave oven transformers.

Type 419- Uncalendered paper with mica

Uncalendered precursor for Type 418, available in 2 thicknesses - 7 and 13 mils (0.06 to 0.33 mm). Highly saturable, with good voltage endurance. Weak physical properties limit its use.

Standard Width : 914mm (36")

| Type | Thickness Inches | Initial Tear Strength | Tensile Strength | Approx. Lenght | Weight

Kgs. Approx. |

Dielectric Breakdown | |||

|---|---|---|---|---|---|---|---|---|---|

| lbs. | lbs./in. | 11-1/2"OD | |||||||

| Machine | Cross | Machine | Cross | Meter | Lineal Yds. | Volts | |||

| 418 | 0.003 | 0.8 | 1.8 | 18 | 12 | 613 | 670 | 50 | 2500 |

| 418 | 0.005 | 1.7 | 3.0 | 31 | 23 | 439 | 480 | 59 | 4450 |

| 418 | 0.008 | 2.9 | 5.4 | 53 | 38 | 293 | 320 | 62 | 8100 |

| 418 | 0.010 | 3.7 | 7.0 | 65 | 48 | 229 | 250 | 62 | 10200 |

| 418 | 0.014 | 4.8 | 8.5 | 85 | 58 | 146 | 160 | 51 | 12900 |

| 419 | 0.007 | 0.6 | 0.3 | 11 | 7 | 329 | 320 | 26 | 2275 |

| 419 | 0.013 | 1.2 | 0.8 | 17 | 12 | 192 | 160 | 26 | 4225 |

Type E-56- Medium-density calendered aramid paper

(An experimental grade of NOMEX® paper)

This newer smooth, calendered, medium-density NOMEX® has been developed in thickness from 5 through 20 mils (0.13 through 0.51 mm) as a less-expensive alternative to Type 410 where properties between those of T-410 and T-411 are needed. The price is approximately 30% less than Type 410, while the calendered properties of E-56A are adequate for many layer insulation uses.

5, 7, 10, 12, 15, and 20 mils (.13, .18, .25, .30, .38, .51 mm)- intended for layer insulation and similar less-demanding ares where Type 410 may be more than is needed but Type 411 properties are not adequate. Can be laminated for motor use. Acceptable in all UL-Recognized insulation systems on a dielectric strength substitution basis for Type 410 or as otherwise included through specific testing.

Type E-196 Saturable NOMEX®

Type E-196 Saturable NOMEX®

NOMEX® E196 paper provides the unique combination of two properties; Saturability and the Stiffness of a paper structure. Resins quickly penetrate the paper, providing a fully saturated structure in a short period of time. Unlike saturable fabric materials, NOMEX® E196 is a stiff, mechanically tough paper. And, NOMEX® E196 is made from the NOMEX® ingredients found in our commerically available papers, so it exhibits the similar long term thermal stability.

Benefits as Motor Phase Insulator:

of motor end-turns.

end-turns.

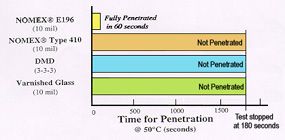

Comparative Penetration Testing:

NOMEX® E196 allows resins to quickly penetrate through its structure. Typical insulating material don't allow penetration at all. Comparative testing of polyester based trickle resin penetration demonstrates the advantage of NOMEX® E196. (ASTM D202)