QiC 107i Thermal Transferprinter |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A freely programmable intermittent Thermal Transferprinter for printing variable text, with a maximum print area of 107 x 107 mm. A freely programmable intermittent Thermal Transferprinter for printing variable text, with a maximum print area of 107 x 107 mm. Large savings are made possible by printing directly onto the packaging film. Synchronisation with a packaging machine is a standard option. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highlights of the Kortho QiC 107i Thermal TransferprinterFreely programmable printer for printing variable textGood product traceability through time and sequence number coding Large savings possible by printing directly on the packaging film No chance of leakage of modified atmosphere packaging through low operating temperature and low pressure Preheat printhead function for use in low environment temperatures Synchronisation with a packaging machine is a standard option. Small installation dimensions Print area up to 107 x 107 mm Various standard sizes of thermal ribbon up to 450 metres long Low noise emission, low maintenance and operator-friendly Creation of images takes place using the universal Kortho QiC Draw or third-party software Nicelabel Data transfer between Nicelabel/QiC Draw and the QiC printer takes place by Ethernet or USB Thermal ribbon change within a few seconds 10.4” full-color touch screen controller QiC DRAW/NICELABEL Images are designed using Kortho QiC Draw or Nicelabel. The printing surface of maximum 107 x 107 mm is completely free to arrange. Images are designed using Kortho QiC Draw or Nicelabel. The printing surface of maximum 107 x 107 mm is completely free to arrange.An image can be filled with text, logos, time, date, best before date, barcodes, batch numbers and shift codes in various types of presentation. The transfer of the images designed takes place using a serial-, Ethernet- or USB- Connection. During printing, the operator can change various parameters online for optimum quality of the print result. The machine operator can select the images to be printed using the full-color touch screen keyboard on the Controller. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

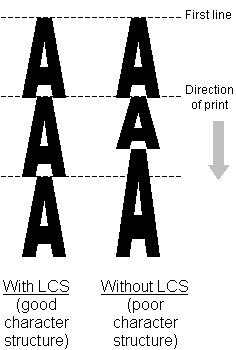

QiC LINEAR CONTROL SYSTEM (LCS) An important parameter of all coding and marking systems is their ability to accurately place and reproduce the desired printed image. An important parameter of all coding and marking systems is their ability to accurately place and reproduce the desired printed image.Barcodes rely upon accurate spatial positioning where the width of a single bar and its distance from its neighbour are crucial elements when later scanned. Similarly, image detection systems work best with characters that are the correct height and exact shape. The QiC coding and marking systems benefit from the use of patented LCS technology to constantly monitor the position of the printhead and synchronise lines of print to be produced precisely and accurately along the length of the format being produced. The LCS fitted to the QiC coders enables the highest quality of print to be constantly produced even as the system naturally wears over time. The LCS automatically detects the need for servicing as it works harder, and provides ample notice to schedule appropriate routine maintenance without loss of production. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

QiC Dynamic Monitoring System (DMS) Thermal Transfer coding and marking devices are complex systems using a combination of software, electronics and mechanics. Over time the mechanical systems wear and the electronics age ultimately leading to failure. The QiC series of Thermal Transfer printers incorporate a ‘Dynamic Monitoring System` (DMS) to constantly check the critical elements of the device and analyse system performance and condition. Thermal Transfer coding and marking devices are complex systems using a combination of software, electronics and mechanics. Over time the mechanical systems wear and the electronics age ultimately leading to failure. The QiC series of Thermal Transfer printers incorporate a ‘Dynamic Monitoring System` (DMS) to constantly check the critical elements of the device and analyse system performance and condition.The areas monitored include: - Voltage rails and power distribution circuits - Air pressures, flow rates and pneumatic seals - Mechanical surface and bearing friction - Internal temperatures - Usage All these measurements and parameters are brought together in real-time by the powerful state-of-the-art Digital Signal Processor (DSP) within the printer. The DSP analyses the continuous stream of data and assesses the overall condition of the system, automatically making suitable adjustments to deliver optimum performance and print quality. The QiC series of Thermal Transfer coders incorporate DMS (Dynamic Monitoring System) which constantly assesses the condition of the printing system and makes adjustments to best maintain performance and quality. The many measurements and parameters monitored by the DMS are brought together and presented on a simple Health Check Indicator. With the arrow in the Green area, the user can be confident the system is working correctly and servicing is not required. As the system detects faults (for example small leaks, worn bearings) the arrow moves into the Amber area. This advises the user that servicing should be scheduled at the earliest opportunity, yet without the immediate need to stop the production line. With regular servicing the arrow should not descend into the red area indicating the printer has a serious problem where quality and performance are likely to be adversely affected. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Contact us

P.LEO & Co,.Ltd

Tel:(852) 2604 8222

Fax:(852) 2693 2093

Eamil: market@pleo.com

Int’l Electrotechnical Co,.Ltd

Tel:(852) 2604 8222

Fax:(852) 2690 2778

Eamil:sales@iec-international.com