To maintain advanced current high-tech industry, HKCC performs to manufacture and supply major essential electric component " Core " for transformers, audio/video equipment's, home appliances, vehicle, Robot, computer etc.

To maintain advanced current high-tech industry, HKCC performs to manufacture and supply major essential electric component " Core " for transformers, audio/video equipment's, home appliances, vehicle, Robot, computer etc.

HKCC contribute to develop the advanced level of high technology in precision carbide dies in Korea, and constantly do the best effort to develop and challenge to the most advanced high-technological core producing in the world.

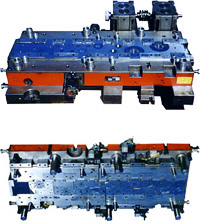

Tool & Dies

The system do layer-building of the cores drawn on the one-piece basis by mold into the number of layers required by customer, and provides inclination per block to minimize noise or vibration.

The system do layer-building of the cores drawn on the one-piece basis by mold into the number of layers required by customer, and provides inclination per block to minimize noise or vibration.Based on the advanced technology and know-how accumulated by production of E&I and MOTOR CORE and manufacturing of mold for over 20 years, Hankook Core has developed CORE mold using super-precision AC/DC turning by means of the state-of-the-art CAD/CAM, which enables the company to reduce cost, achieve high quality products and contribute to the strengthening of our competitiveness on the world market. Also our super-precision technology shows world-class level. Hankook Core do its best to extend the service life of mold and develop complex large precision mold on the basis of continuous R&D.

|

The rotor shaft of a motor requires a bore with a one or two steps to accomodate the bearing. Our Stacking System supply the method to counterbore by simple presetting the number of lamina. |

|

Rotor cores are skewed to minimize the abnomal noise and vibration and to increse the performance. Our Stacking System serves to skew the lamina at any angle when fastening rotor cores. |

|

The lamina pressed in the die is stacked with a various kind of fastenning methods and can be extracted with required number of laminas. |

|

Touch Screen method and help function were used so the use is very convenient. Version up and adding an additional function can be easily upgraded hereafter only to change and modify the program. |

Zhongshan Guodian Trading Co,.Ltd.

Zhongshan Guodian Trading Co,.Ltd.